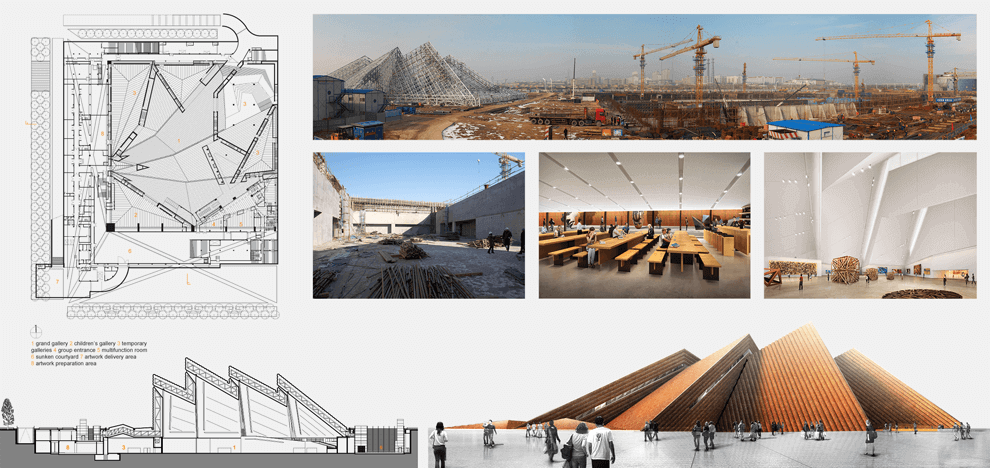

Datong Art Museum

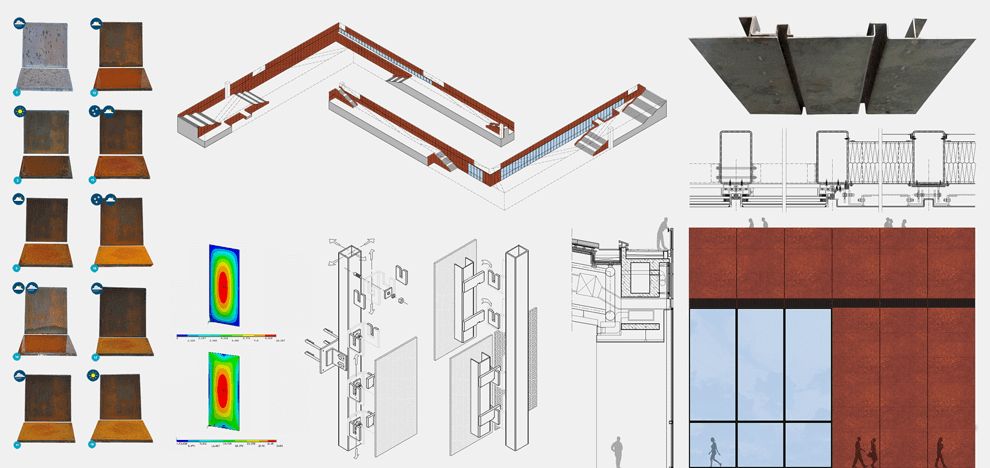

The 36000m2 museum in Shanxi is conceived as an erupted landscape in the city’s new cultural plaza. The gallery level is set at -12m allowing the massive steel structure to create a 37m high gallery space. Entry takes place through a sunken plaza at the northeast corner. Smaller galleries, group entrance lobby, café, restaurant and support spaces are arranged around the grand gallery. A sunken courtyard surrounds the building from the south and west sides. Art preparation areas are housed under grade landscape. Construction started Oct 2011 and is set for completion Aug 2013. The building is clad in 32000m2 earth-toned weathering steel + 4000m2 glazing. Coating is applied to the steel after 2 months of controlled weathering. Flat panels are installed at the courtyard while curved panels are used on the roof. The panels are top hung with 6mm expansion joints horizontally and 40mm shadow gaps vertically at 2.5m grids. The cladding is designed as a rain-screen system with water proofing behind. The glazed areas consist of triple glazed heat-strengthened glass that is silicon bonded to aluminium carriers and mechanically retained by 12mm aluminium frames.

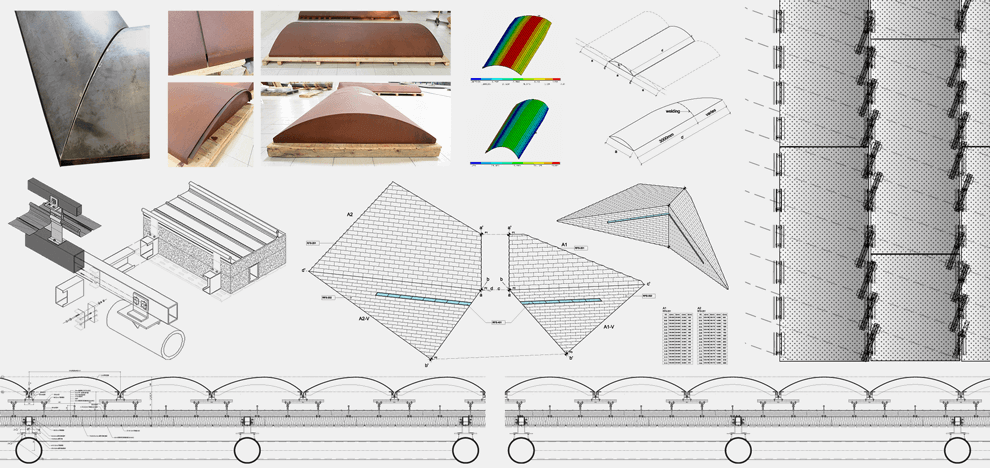

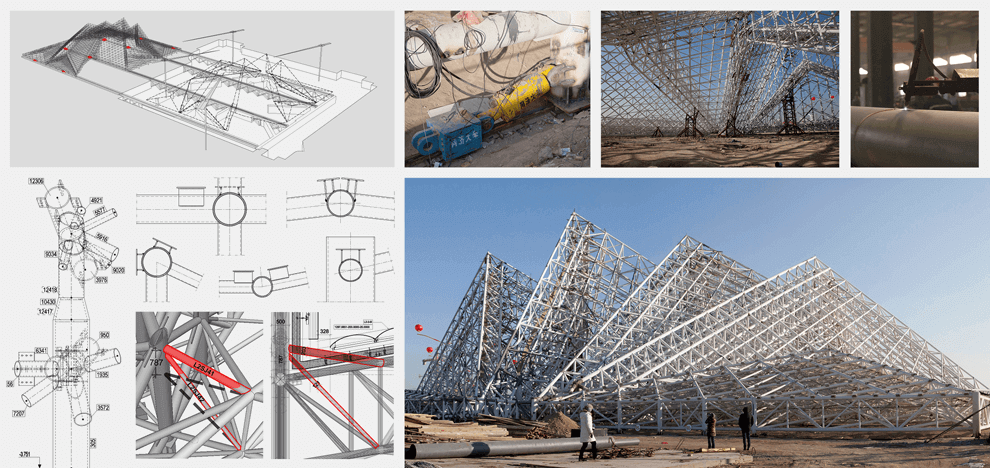

The roof accounts for 70% of the exposed surface area. Skylights are carved out each of the four vertical roof surfaces. The eastern roof planes acts as panel form generators with 200mm deep single arc panels while the western panels are composite curve resultants. This ensures the two faces node out at the ridges. The panels are bent using CNC rollers while stiffening ribs are manually welded to the undersides. Each panel is attached to the standing seam through 12 flexible connection points. Typical panels measure 3m in length while its width varies from 0.9m to 1.3m. The steel structure was coordinated through clash detection tests. Member assembly took place 180m south of the actual structure end location. Tube diameters range from 80-700mm with a truss depth of 3.5-4.5m spanning a maximum of 80m. Working on both the concrete and steel structure simultaneously, the team was able to save 5 months of construction time. After completion, the 4000 ton structure was sled along 6 tracks using 12 hydraulic crawlers. The process lasted 5 days with speeds up to 8m/h. The load was then transferred onto plinths embedded in concrete shear walls.