TAVR Simulation

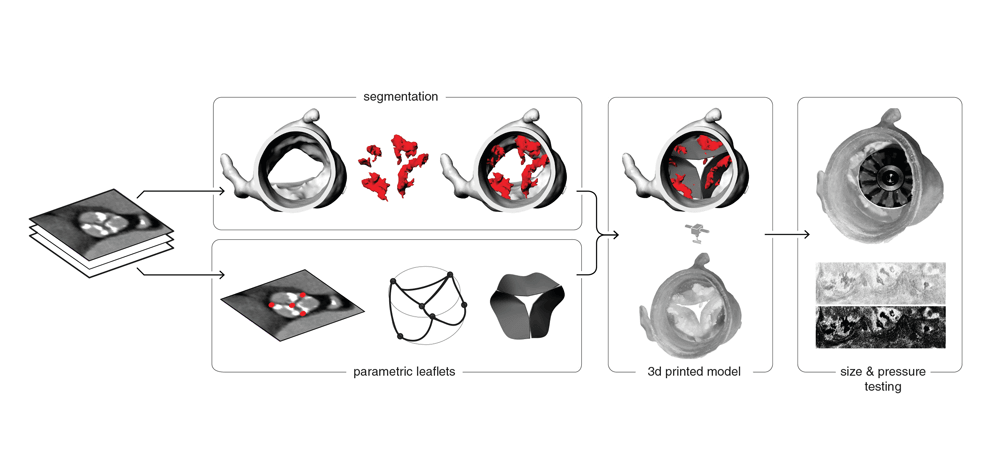

Background. Successful transcatheter aortic valve replacement (TAVR) requires an

understanding of how a prosthetic valve will interact with a patient’s anatomy in advance of

actual deployment. To improve this understanding, we developed a benchtop workflow that

allows for testing of physical interactions between prosthetic valves and patient-specific aortic

root anatomy, including calcified leaflets, prior to actual prosthetic valve placement.

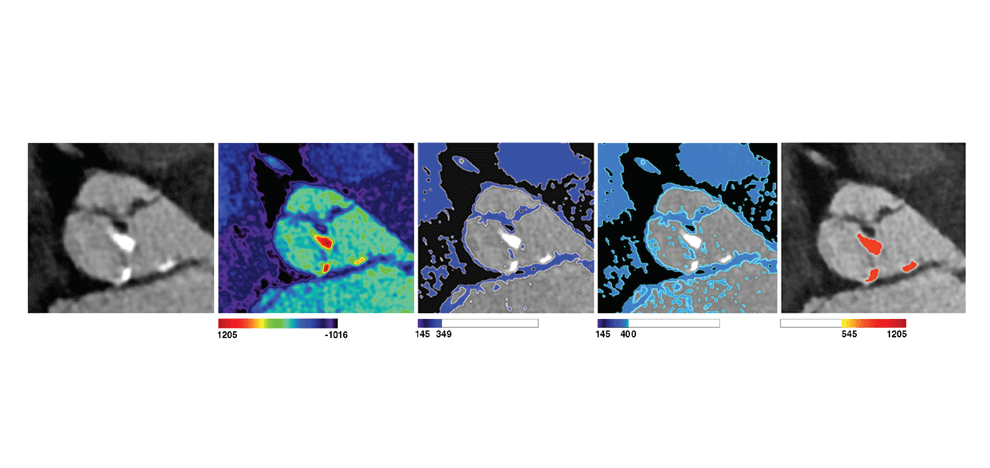

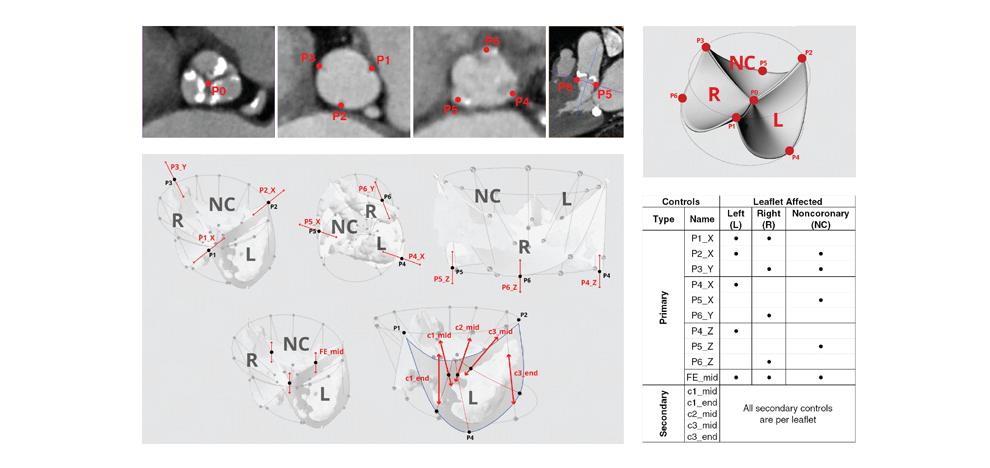

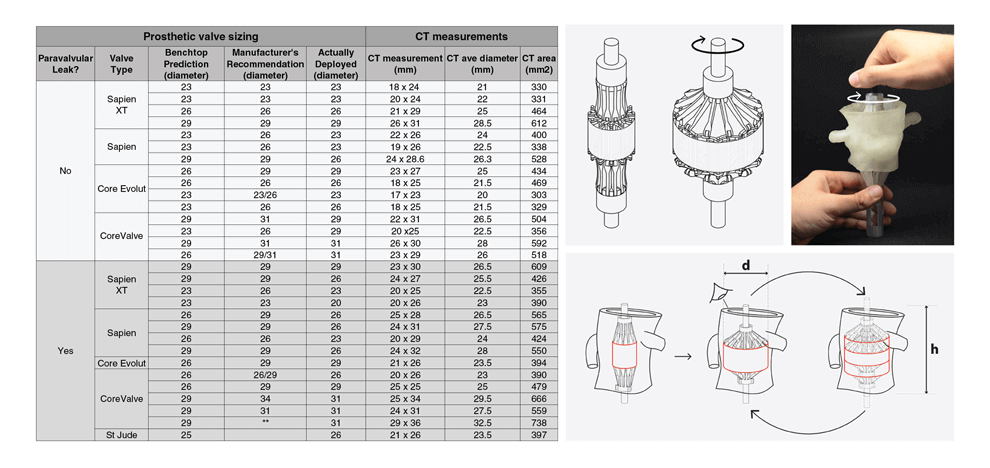

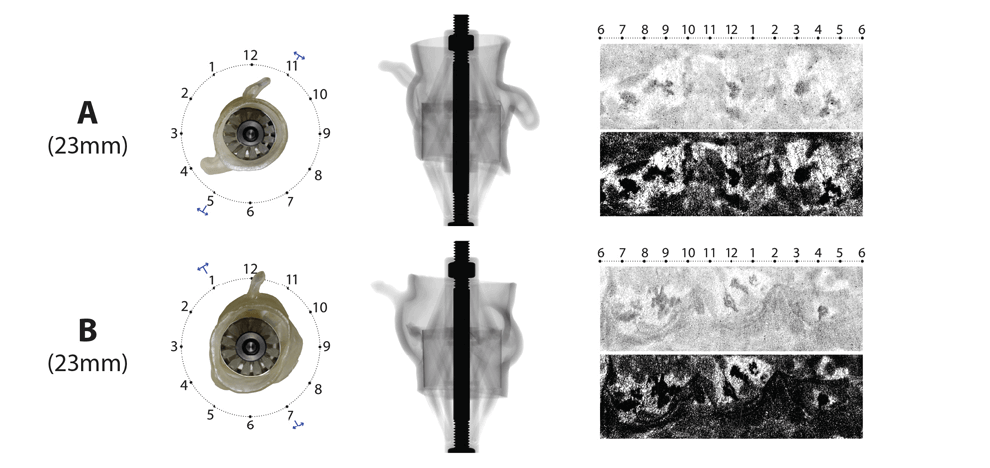

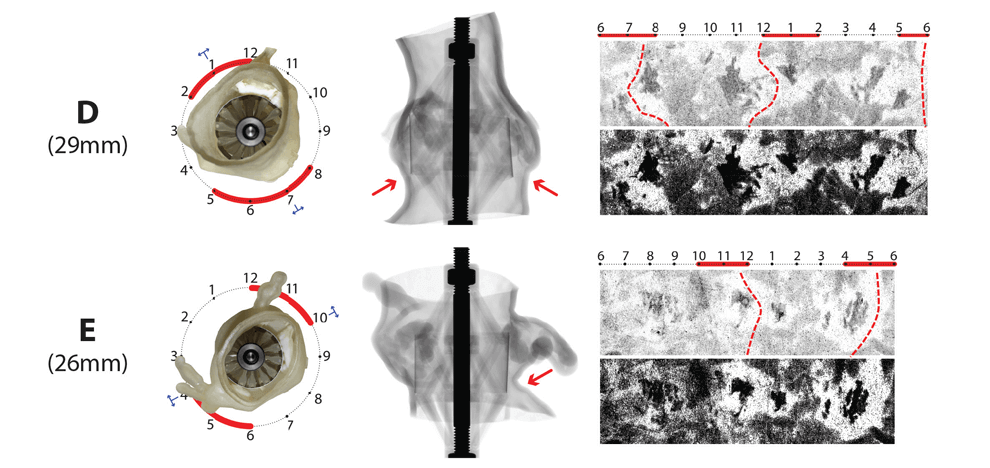

Methods. This was a retrospective study of 30 patients who underwent TAVR at a single high

volume center. By design, the dataset contained 15 patients with a successful annular seal

(defined by an absence of paravalvular leaks) and 15 patients with a sub-optimal seal (presence

of paravalvular leaks) on post-procedure transthoracic echocardiogram (TTE). Patients received

either a balloon-expandable (Edwards Sapien or Sapien XT, n=15), or a self-expanding

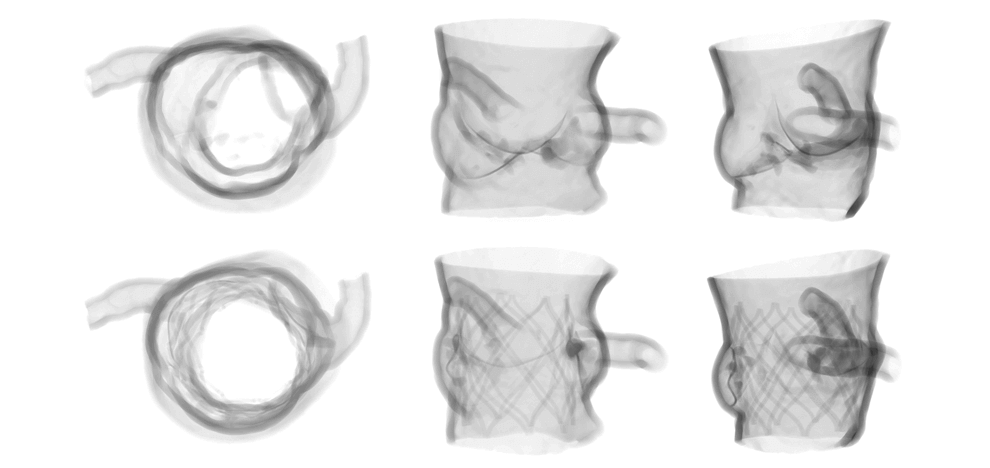

(Medtronic CoreValve or Core Evolut, n=14, St. Jude Portico, n=1) valve. Pre-procedural

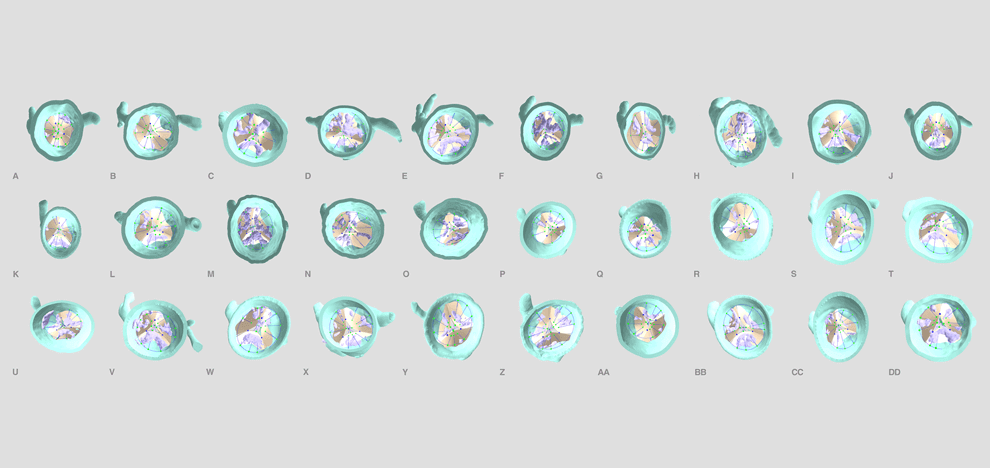

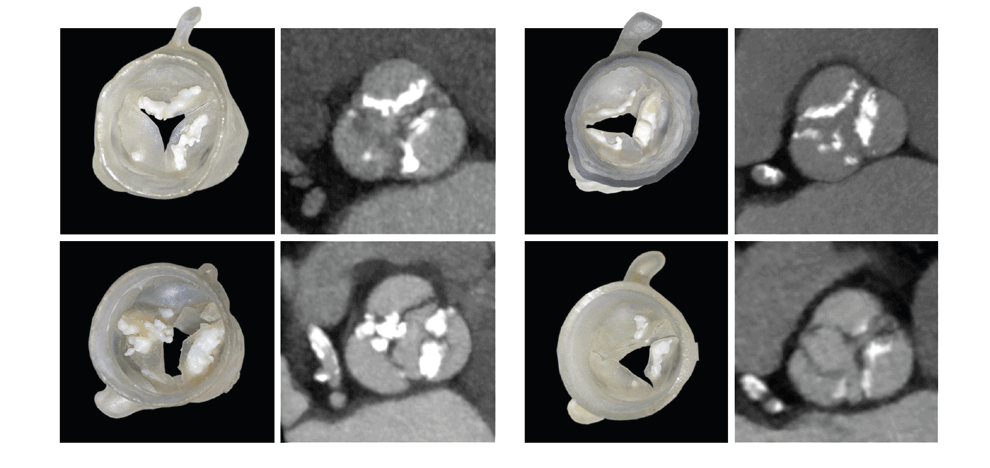

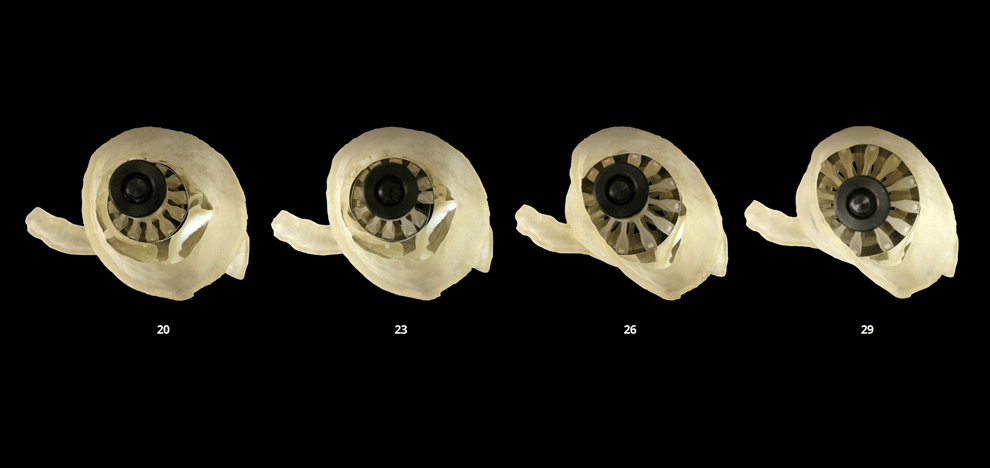

computed tomography (CT) angiograms, parametric geometry modeling, and multi-material 3D

printing were utilized to create flexible aortic root physical models, including displaceable

calcified valve leaflets. A 3D printed adjustable sizing device was then positioned in the aortic

root models and sequentially opened to larger valve sizes, progressively flattening the calcified

leaflets against the aortic wall. Optimal valve size and fit were determined by visual inspection

and quantitative pressure mapping of interactions between the sizer and models.

Results. Benchtop-predicted “best fit” valve size showed a statistically significant correlation

with gold standard CT measurements of the average annulus diameter (n=30, p < 0.0001

Wilcoxon matched-pairs signed rank test). Adequateness of seal (presence or absence of

paravalvular leak) was correctly predicted in 11/15 (73.3%) patients who received a balloonexpandable

valve, and in 9/15 (60%) patients who received a self-expanding valve. Pressure

testing provided a physical map of areas with an inadequate seal; these corresponded to areas of

paravalvular leak documented by post-procedural transthoracic echocardiography.

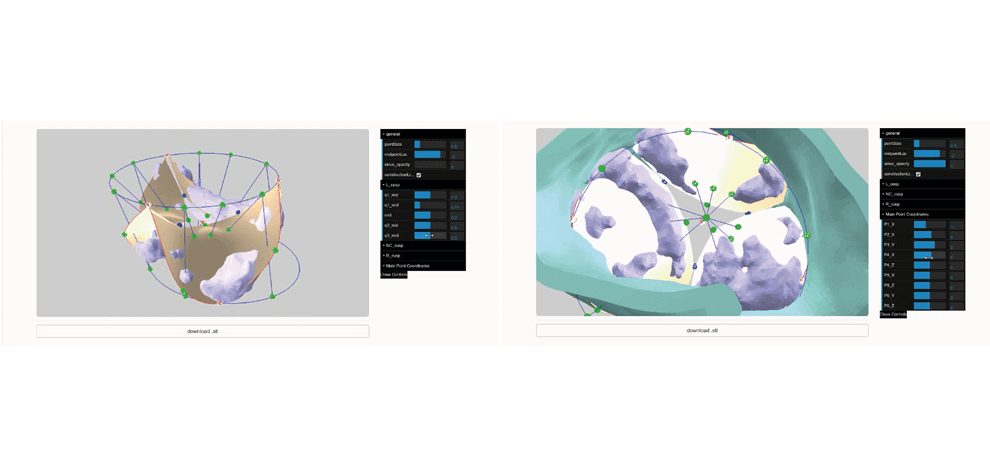

Conclusion. We present and demonstrate the potential of a workflow for determining optimal

prosthetic valve size that accounts for aortic annular dimensions as well as the active

displacement of calcified valve leaflets during prosthetic valve deployment. The workflow’s

open source framework offers a platform for providing predictive insights into the design and

testing of future prosthetic valves.

The manuscript was published in the Journal of Cardiovascular Computed Tomography and can be found here, in addition to the web app, github repository, and sizing hardware.